Описание

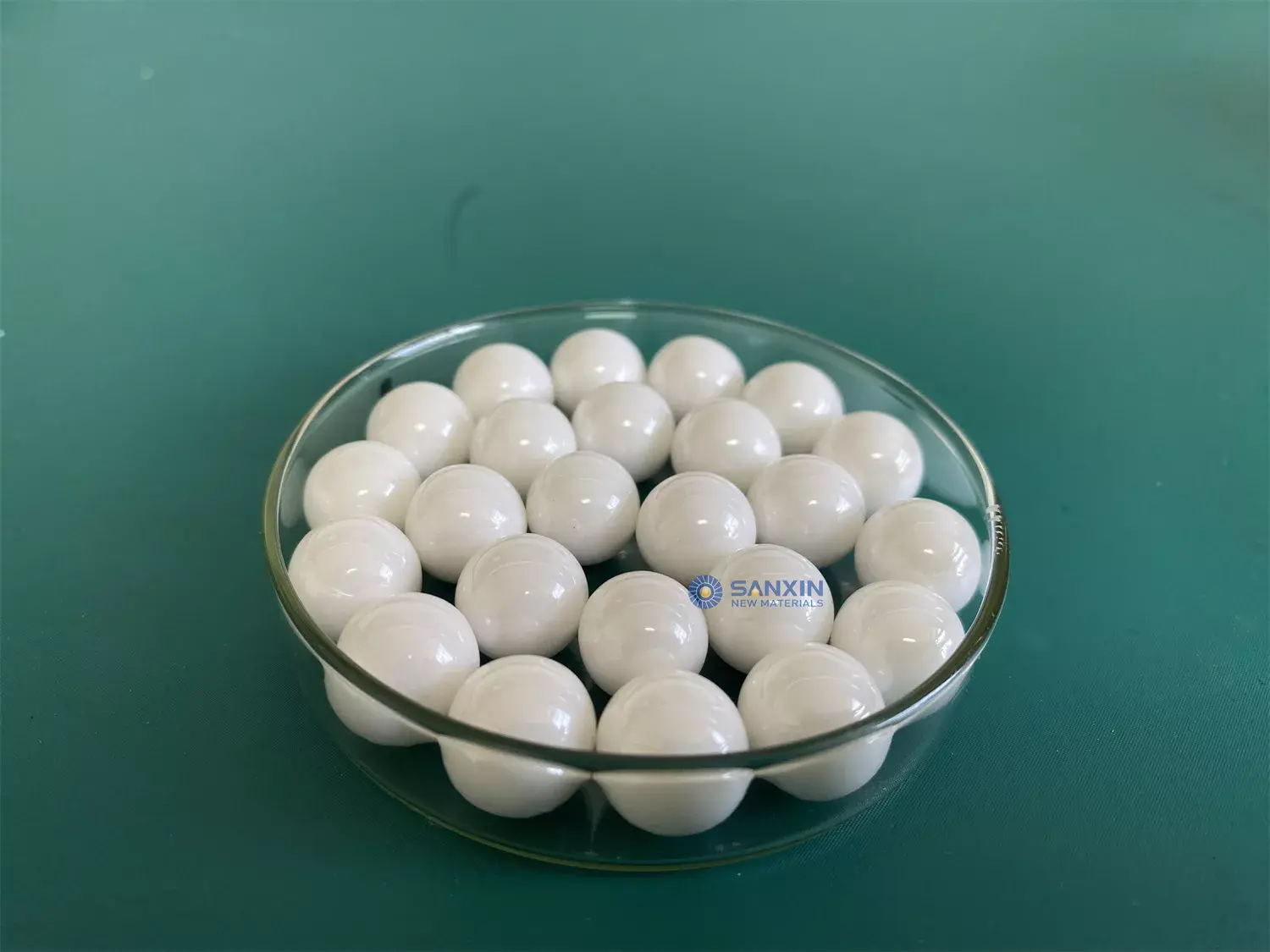

Zirconium beads go by many names around the world: Mahlperlen in Germany. Bolas de Moliendas in South America. Pearls in Europe. Zirconia beads in Asia. But whichever corner of the globe you call home, whatever you call the beads, one thing is clear— Sanxin Zirconia beads Grinding Media is the right ceramic grinding media for you.

Zirconia microsphere (SXYZV Series) are produced using high-quality yttria-stabilized zirconia powder through the latest hydrolysis process. These beads exhibit outstanding grinding efficiency, thanks to their high crushing strength and minimal wear loss. They adhere to international standards in terms of quality and properties, making them reliable and effective grinding media. Zirconia microsphere beads are well-suited for grinding materials to the nano size range, including electronic ceramics, ceramic ink, MLCC (multi-layer ceramic capacitors), CMP (chemical mechanical planarization), and photo catalysts.

The utilization of high-quality yttria-stabilized zirconia powder in the manufacturing process ensures the beads’ excellent properties. The hydrolysis process enables the production of uniform and finely controlled microspheres, which contribute to their enhanced grinding performance. These beads possess a high crushing strength, enabling them to withstand significant forces during grinding without breaking or deforming. This durability ensures extended usage life and consistent grinding results.

Furthermore, zirconia microsphere grinding beads exhibit minimal wear loss, even under demanding grinding conditions. This low wear characteristic allows for prolonged usage and maintains the beads’ shape and size, resulting in stable and precise grinding outcomes. Additionally, their high wear resistance reduces the risk of contamination, ensuring the purity and integrity of the ground materials.

Zirconia microsphere beads are specifically designed for grinding materials down to the nano size, enabling the production of finely ground particles with controlled size distributions. They are particularly suitable for applications involving electronic ceramics, ceramic ink, MLCC, CMP, and photo catalysts, where achieving precise particle sizes is critical for optimal performance.

In conclusion, zirconia microsphere grinding beads made from high-quality yttria-stabilized zirconia powder via the hydrolysis process offer exceptional grinding efficiency. Their high crushing strength, low wear loss, and adherence to international quality standards make them reliable and effective grinding media. These beads are well-suited for grinding materials to the nano size range in various industries, including electronic ceramics, ceramic ink, MLCC, CMP, and photo catalysts, ensuring precise and high-quality grinding results.

SXYZV Properties

| Type |

Density (g/cm3) |

Bulk density (g/cm3) |

Major composition (%) |

Crush strength (N) |

V-Hardness (HV10) |

| SXYZV |

≥6.0 |

≥3.6 |

ZrO2:94.6 Y2O3:5.2 |

≥90 (Ø0.3mm) |

≥1250 |

Size

Ø 0.05mm, Ø 0.1mm, Ø 0.2mm, Ø 0.3mm (Nano grinding)

Customization size available

Application

Note

(1) Hazards identification

l Health Rating: 0 – None

l Flammability Rating: 0 – None

l Reactivity Rating: 0 – None

l Contact Rating: 0 – Slight

Potential irritation may occur through abrasive friction.

Risk of slipping exists when the product (beads) is scattered on the floor.

While the product is not expected to cause inhalation issues, its use can generate dust.

(2) First Aid Measures Eyes: Possible abrasion through friction; treat as a particle in the eye.

(3) Fire Fighting Measures:This product is non-combustible and non-explosive. It is compatible with standard firefighting methods.

(4) Accidental Release Measures

l Isolate the area and sweep the floor to collect beads, preventing slipping by rolling.

l Use eye protectors and a dust mask.

(5) Handling and Storage

l When operations generate dust, use a dust mask and eye protectors.

l Adhere to safety rules for storing this heavy material, and wear safety shoes during handling.

(6) Physical/Chemical Properties

l Appearance and Odor: Odorless Yellow beads

l Solubility in Water: Insoluble

l Volatiles by Volume at 21℃: 0%

l Boiling Point: NAIF

l Melting Point: Over 1600℃

(7) Disposal Consideration

Any portion that cannot be salvaged for recovery or recycling should be handled at an appropriate waste disposal facility.

Dispose of packaging and unused contents in accordance with governmental and local requirements.

(8) Transport information: Not regulated