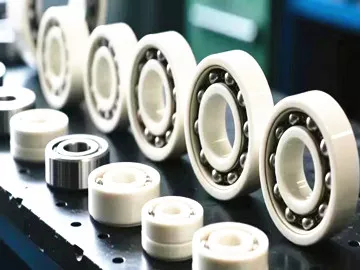

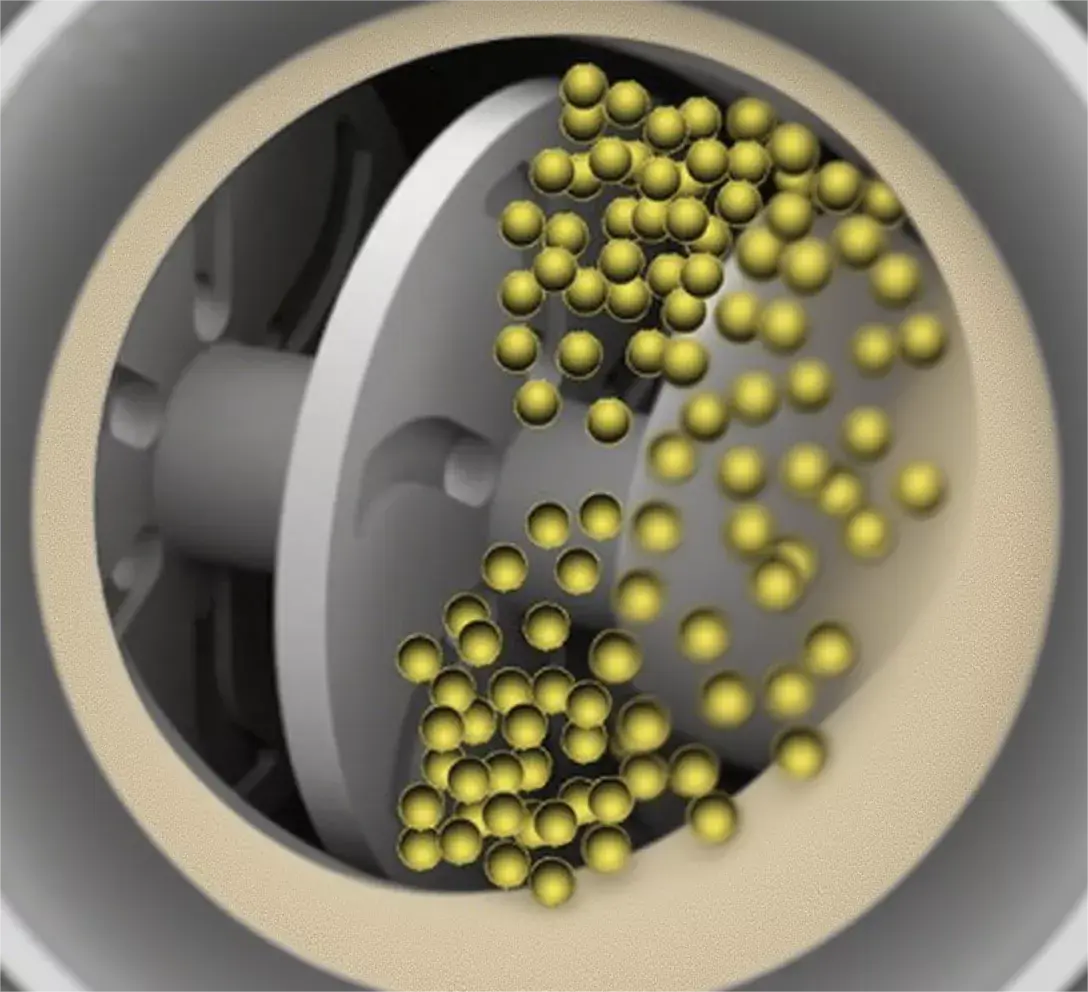

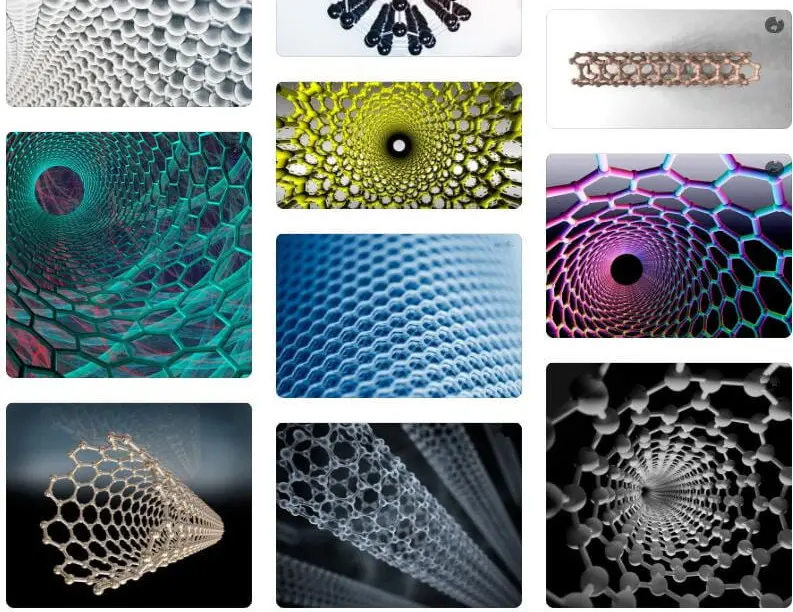

Welcome to the world of advanced industrial ceramics

About Sanxin New Materials

Jiangxi Sanxin New Materials Co., Ltd. is a trusted leader in the industrial ceramics industry, offering unrivaled expertise and innovative solutions, tailored to your needs. That's why global customers choose Sanxin for their ceramic grinding media and advanced ceramic materials needs:

More 18 years of industry leadership: S 2008 Sanxin pioneers the development of ceramic grinding media and advanced ceramic materials, offering advanced solutions in zirconium oxide products, aluminum oxide, silicon nitride and silicon carbide. Our extensive experience guarantees precisely engineered ceramic materials, meeting the most stringent industry standards.

Request a quick quote