Silicon Carbide Ceramics SiC: Properties, options, applications and innovations

Silicon Carbide Ceramics (SiC): properties, types and individual solutions

Professional silicon carbide ceramic solutions

We are ready to answer any questions and provide detailed information about our silicon carbide ceramic products (SiC), and comprehensive engineering and manufacturing services. No matter, whether you are in the development phase of a custom prototype or scaling up mass production for extreme industrial environments, our team of experts will help you get the most out of this high-performance material.

SiC ceramics are widely used in mining, energy, chemical, metallurgical and semiconductor industries, where high wear resistance is required, heat resistance and chemical inertness.

Customized Silicon Carbide Ceramic Components

We manufacture silicon carbide components strictly according to customer specifications. All key parameters can be configured:

-

chemical purity and type of SiC (black, green, RBSC, SSC, CVD)

-

microstructure and phase composition

-

dimensional tolerances and geometry

-

finishing machining

Our completed projects include:

-

high precision abrasive products

-

fire-resistant and wear-resistant linings

-

substrates and wafers for semiconductors

-

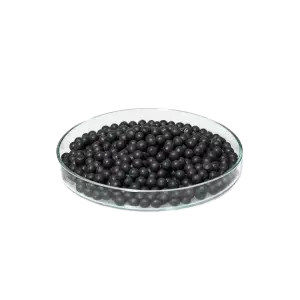

ceramic balls made of SiC for grinding ores and cement

Ready to develop custom SiC parts? Contact us - our engineers work with CAD models and rapid prototyping technologies, which allows you to significantly reduce the time it takes to bring products to market.

The Complete Guide to Silicon Carbide Ceramics

History of silicon carbide

Silicon carbide (SiC) was opened in 1893 by American chemist Edward Goodrich Acheson. In the process of experiments on the synthesis of diamond, he obtained the material, later called "carborundum", which became the first artificial abrasive, produced on an industrial scale.

Thanks to its hardness 9,5 Mohs scale, SiC already replaced natural abrasives at the beginning of the 20th century.. In the 1920s, it began to be actively used in refractory materials and industrial furnace linings.. After World War II, its semiconductor properties were discovered, including wide bandgap (~3.26 eV), making SiC a key material for power electronics.

Since the 1980s, the development of CVD technologies has made it possible to obtain ultra-pure silicon carbide for LEDs, MOSFET transistors and high voltage devices. Today, global production exceeds 1,5 million tons per year, and the SiC market is valued at more than 5 billion dollars, what do electric cars contribute to?, renewable energy and 5G networks.

Properties and advantages of silicon carbide ceramics

Silicon carbide ceramics is a non-oxide covalent material with a unique combination of mechanical properties., thermal and chemical properties:

-

density: ~3.2 g/cm³ (significantly lower than steel)

-

hardness: HV ≈ 2100

-

bending strength: to 400 MPa

-

operating temperature: to 1600 °C

-

thermal conductivity: 90-490 W/m·K

-

coefficient of thermal expansion: ~3,5 × 10⁻⁶ K⁻¹

SiC is resistant to oxidation, corrosion, thermal shock and exposure to most acids and alkalis (except HF). Its self-lubricating microstructure ensures a low coefficient of friction (<0,2), which makes the material ideal for abrasive and dynamically loaded components.

Despite the higher cost compared to aluminum oxide, the service life of SiC products is 10–20 times higher, resulting in low total cost of ownership (TCO) and high economic efficiency.

Types of Silicon Carbide Ceramics

SiC ceramics are available in various modifications, optimized for specific tasks.

Black silicon carbide (Black SiC)

Description:

Produced in Acheson kilns at temperatures of 2200–2500 °C from quartz sand and petroleum coke. SiC content - 97–99%, iron impurities are present.

Advantages:

Application:

Grinding wheels, fireproof materials, wear plates, as well as SiC ceramic balls for grinding mills in the mining and cement industries.

| Property |

Units. change. |

Test standard |

Black SiC |

Green SiC |

RBSC |

SSC |

CVD SiC |

| Material |

– |

– |

Black |

Green |

Porous |

Dense |

Film |

| Density |

g/cm³ |

ISO 18754 |

3,15 |

3,20 |

2,7 |

3,10 |

3,21 |

| Bending strength |

MPa |

ASTM C1161 |

400 |

450 |

250 |

400 |

500 |

| Compressive strength |

MPa |

GB/T 8489 |

2000 |

2200 |

1500 |

2000 |

2500 |

| Young's modulus |

GPa |

ASTM C1198 |

430 |

450 |

300 |

410 |

460 |

| Fracture toughness |

MPa·m¹/² |

ASTM C1421 |

4 |

4,5 |

3 |

4 |

5 |

| Poisson's ratio |

– |

ASTM C1421 |

0,16 |

0,16 |

0,17 |

0,16 |

0,15 |

| Hardness HRA |

HRA |

Rockwell 60N |

94 |

95 |

92 |

94 |

96 |

| Vickers hardness |

HV1 |

ASTM C1327 |

2100 |

2200 |

1800 |

2100 |

2500 |

| Thermal expansion |

10⁻⁶ K⁻¹ |

ASTM E1461 |

3,5 |

3,4 |

3,6 |

3,5 |

3,3 |

| Thermal conductivity |

W/m·K |

ASTM E1461 |

90 |

120 |

50 |

90 |

490 |

| Thermal shock resistance |

ΔT (°C) |

– |

600 |

650 |

500 |

600 |

700 |

| Max. pace. (oxidation) |

°C |

No load |

1350 |

1400 |

1200 |

1350 |

1600 |

| Max. pace. (recovery/inert) |

°C |

No load |

1350 |

1400 |

1400 |

1600 |

2000 |

| Volume resistance (20°C) |

Ohm cm |

– |

10⁵ |

10⁴ |

10⁶ |

10⁵ |

10³ |

| Dielectric strength |

kV/mm |

– |

0 |

0 |

5 |

0 |

0 |

| Dielectric constant (1 MHz) |

– |

ASTM D2149 |

N/A |

N/A |

10 |

N/A |

N/A |

| Dielectric losses (20°C, 1 MHz) |

tan δ |

ASTM D2149 |

N/A |

N/A |

10⁻² |

N/A |

N/A |

Note: Values for sintered grades; CVD exceeds (conductivity 490 W/m·K, purity 99,9995%).

Benchmarking for Precision Engineering

SiC excels in conductivity/hardness, superior to oxides in semiconductors/heat. Extended comparison with metals/ceramics:

| Characteristic |

SiC ceramics |

Aluminum Oxide Ceramics |

Steel alloys |

Tungsten carbide |

| Strength and Toughness |

High (K_IC 4) |

Compression-strong, fragile |

Ductile, prone to fatigue |

High, fragile |

| Thermal stability |

Excellent (1600°C) |

Excellent (1800°C) |

good (~800°C) |

Fireproof (2800°C) |

| Wear resistance |

Exceptional (HV 2100) |

Highest level (HV 1500) |

Moderate (rusts) |

Elite (HV 2000) |

| Corrosion resistance |

Highly inert |

Excellent (acids) |

Inclined |

Strong (acids) |

| Transparency |

Opaque (translucent CVD) |

Translucent |

Opaque |

Opaque |

| Biocompatibility |

High (ISO 10993) |

High |

Varies (toxic) |

Varies |

| Electrical insulation |

Semiconductive (10⁴–10⁵ Ohm cm) |

Excellent |

Conductive |

Conductive |

| Magnetic behavior |

Non-magnetic |

Non-magnetic |

Ferromagnetic |

Non-magnetic |

| Price (per kg) |

Moderate ($20–50) |

Low ($5–20) |

Low ($1–5) |

High ($100+) |

| Density (g/cm³) |

3,2 |

3,9 |

7,8 |

15,6 |

Advantages of Silicon Carbide Ceramics

SiC attributes provide life cycle benefits:

- Durability: Hardness gives 10-30 times life in abrasives/grinding balls, downtime -60% in the mills.

- Adaptability: From -50°C to 1600°C, from cryo to plasma in a wide range of applications.

- Lightness: 60% steel, aero efficiency +10%; grinding balls reduce the load on the mill.

- Minimal Maintenance: Impact ΔT 600°C, no deformation in heat/refractory.

- Economic value: Energy saving 40% in semiconductors, fast ROI; Grinding balls reduce contamination.

- Environmental safety: Low emissions in EV; recyclable for green mining.

- Reliable Performance: Fatigue >10⁷ cycles; rigid for precision armor.

- Friction durability: Self-lubricating μ<0,2, power loss -20% in the nozzles.

- Friendly to the body: Osseointegration 95%, low implant wear.

- Thermal efficiency: Conducts in 5 times better than aluminum oxide, compact radiators for LEDs.

- Chemical inertness: Resistant to corrosion without HF, vital for chemical pumps.

- Bandgap versatility: 3 eV for blue LEDs up to 1200 In power in EV.

Real Applications of Silicon Carbide Ceramics

SiC shines at abrasive/electronic extremes, its hardness/conductivity is irreplaceable. Below are the expanded top 10:

Top 10 Applications in Modern Industries

- Silicon Carbide Grinding Balls: High-density media in ball mills, export to 10 times lower than steel, grinding efficiency +25%.

- Abrasives: Grinding wheels and sandpaper, removal of material in 3 times faster.

- Refractories: Furnace linings, 1600°C shock resistance.

- Semiconductors: MOSFET/SiC wafers, EV efficiency +30%, range +20%.

- Armor: V50 slabs >1200 m/s, lightweight protection.

- Aerospace: Turbine blades/heat shields at 1400°C.

- Chemical pumps: Valves/nozzles, resistant to H₂SO₄/NaOH.

- Medical implants: Low wear <0,01 mm/year.

- Energy accumulators: High Density Anodes/Capacitors.

- LEDs: Pads +50% efficiency, -40% cost.

Sectors of application

- Industrial: Abrasives, refractories, pumps, grinding balls.

- Electronics: Diodes and transistors for 5G and EV.

- Aerospace: High Temperature Screens and Components.

- Medicine: Biocompatible implants.

- Energy: Batteries and LEDs for renewable energy sources.

The combination of SiC characteristics cements its role in high technology, the market is valued at $10 billion k 2030 year.

Advanced Silicon Carbide Ceramics: Doped and CVD variants

Standard SiC opaque black/green, however CVD and doped (N/B) options give translucency in IR.

- Problems: obtaining defect-free growth.

- Methods: 4H-SiC epitaxy.

- Applications: RF 5G, quantum devices.

- Prospects: nano-SiC 600 W/m·K; high-density composites for ultra-fine grinding.

How silicon carbide ceramic components are made?

SiC components are formed through powder and steam processes for density >99%. Below is the working flow:

1. Preparation of raw materials

SiO₂/carbon mixture or CVD precursors (SiH₄/C₃H₈). For grinding balls - powder <10 µm.

2. Grinding and mixing

Attritor up to 1–5 μm; binders and dopants are added.

3. Forming methods

- Dry pressing: for balls at 200 MPa.

- Suspension casting: for linings.

- CVD: for substrates at 1000°C.

4. Debinderization

Organic removal up to 800°C.

5. Sintering

2000–2200°C, Ar; HP/RBSC; HIP for high density.

6. Final operations

Diamond grinding to Ra 0,01 µm; ball sorting >99% sphericity.

7. Quality control

X-ray, ASTM bending, CMM.

8. Preparation for delivery

Packaging with certificates, scalable to millions of products per year.

Exit: 95%, ISO 9001.