Alumina ceramics (Al₂O₃): properties, history and customized solutions for industry

Alumina ceramics (aluminum oxide ceramics, Al₂O₃) is one of the most popular materials in modern industry due to its combination of high hardness, wear resistance, thermal stability and excellent electrical insulating properties. We are always ready to answer your questions and provide additional information about our alumina ceramic products and comprehensive services. No matter, whether you are developing custom prototypes or scaling up mass production for complex industrial applications, our team will help you unlock the full potential of this unique material.

Customized Alumina Ceramic Components

We offer custom-made aluminum oxide ceramics, adapting each parameter to the specific requirements of the client - from the purity of the initial powder to micron geometry tolerances.

As part of the completed projects, we successfully produced:

-

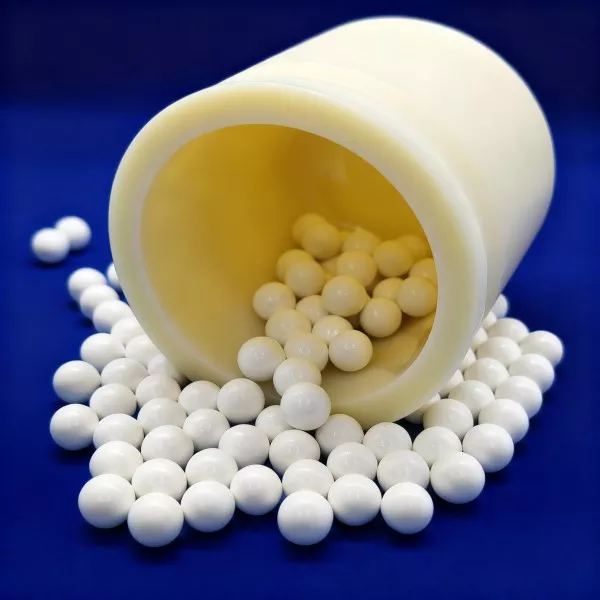

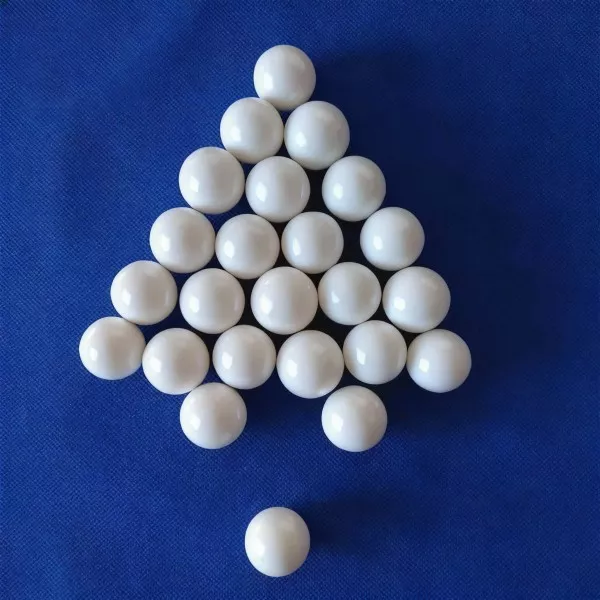

high precision Al₂O₃ grinding balls,

-

wear-resistant pump linings and pipelines,

-

electrical and high voltage insulators,

-

structural and protective elements for aggressive environments.

Ready to start designing custom parts? Contact us today - our engineers can work with you to develop CAD models, perform a quick calculation of parameters and organize accelerated prototyping, significantly reducing time to market for products.

A Comprehensive Guide to Alumina Ceramics

History of alumina ceramics

The history of aluminum oxide ceramics dates back to the end of the 19th century and is associated with the discovery of Al₂O₃ as a natural mineral - in the corner, which has been valued since ancient times for its exceptional hardness and was used in abrasives, and also in precious stones, such as rubies and sapphires.

The key milestone was the invention Bayer process V 1887 year by the Austrian chemist Carl Joseph Bayer. This method made it possible to effectively extract aluminum oxide from bauxite ore, turning the material from a geological rarity into an industry standard for aluminum production.

By the beginning of the 20th century, aluminum oxide was widely used in the form of abrasives for grinding wheels and refractory materials., taking full advantage of its Mohs hardness, equal to 9.

1930-These years were a turning point: commercialization of high-quality synthetic alumina has paved the way for development structural ceramics, going far beyond traditional abrasives. After World War II, electrification and the growth of the aerospace industry accelerated the adoption of alumina ceramics in electronics (including high voltage insulators by the 1960s) and in engine building, where its thermal stability turned out to be critical.

Biomedical applications began to emerge as early as the 1930s, however, mass adoption occurred in the 1970s - primarily in hip replacement - due to the high biocompatibility of the material. Currently, global production of aluminum oxide exceeds 100 million tons per year, which underlines its importance for semiconductors, renewable energy and sustainable production.

Understanding the properties of alumina ceramics

Alumina ceramics, derived from aluminum oxide (Al₂O₃), belongs to the key classes of modern engineering materials. She is known for her:

-

high hardness,

-

excellent electrical insulating properties,

-

wear resistant, corrosion and extremely high temperatures.

Chemically stable α-phase of aluminum oxide (in the structure) Provides exceptional compressive strength at relatively low density 3,6–4.0 g/cm³, which makes the material lighter than steel and at the same time significantly more durable in abrasive conditions.

Due to its technological flexibility, alumina ceramics can be produced in a variety of forms - from micro-precision balls to large-scale structural linings. This makes it the optimal choice for industries, where reliability is required without the typical disadvantages of metals, such as corrosion, fatigue failure and the need for anti-corrosion protection.

Performance Benefits of Alumina Ceramic

The high efficiency of aluminum oxide ceramics is due to the following characteristics:

-

Melting point above 2000 °C,

-

Low thermal conductivity 20–35 W/mK,

-

Excellent dielectric properties.

This makes the material ideal for thermal insulation in ovens, electric motors and high temperature industrial installations. Under severe wear conditions, aluminum oxide ceramics exhibit a wear rate less 0,1 mm3/N·m, and in electrical insulating applications, a dielectric strength of more than 20 kV/mm, effectively preventing electrical breakdowns.

From an economic point of view, Al₂O₃ remains one of the most profitable technical ceramic materials: thanks to the Bayer process it is 30–50 % cheaper than zirconium dioxide, while providing 80–90 % comparable mechanical characteristics under compression conditions.

Environmental and sustainable benefits

Aluminum oxide ceramics have a favorable environmental profile:

This reduces the use of metals in aggressive environments and is consistent with sustainable development and green industry goals up to 2030 year.

Alumina ceramic options

Al₂O₃ based ceramics are available in several purity grades, each of which is optimized for specific operating conditions:

-

92 % Al₂O₃,

-

95 % Al₂O₃,

-

99 % Al₂O₃,

-

99,9 % high purity aluminum oxide,

-

99,99 % ultra high purity aluminum oxide.

Differences in composition allow you to control strength, electrical insulating properties, transparency and resistance to brittle fracture.

Aluminum Oxide Ceramics 92 %

Review:

Industry standard containing approx. 92 % Al₂O₃, providing an optimal balance between cost and durability.

Improvements:

Increased machinability and corrosion resistance due to fine grain structure (2-5 μm).

Applications:

Pump linings, catalyst carriers, Al₂O₃ grinding balls for the cement and mining industries.

Aluminum Oxide Ceramics 95 %

Review:

Most Common Industry Standard for Purity 95 %.

Improvements:

Stable mechanical characteristics, improved machinability and chemical resistance.

Applications:

Pumping systems, catalytic units, mills for cement and minerals.

Key properties of aluminum oxide ceramics

Color and appearance:

Predominantly white or milky white. High purity grades (>99,5 %) can be translucent or almost optically transparent. Surface treatment produces matte or reflective finishes.

Recommendations for use:

Follow the installation instructions or contact our specialists to guarantee stable and long-lasting results.

Main technical characteristics

-

Hardness: Moos 9 (HV 1100–2000), second only to diamond.

-

Crack resistance: K_IC 3–5.5 MPa·m¹/²; high compressive strength, tensile brittleness.

-

Strength: compression 2000–4000 MPa, bending 250–500 MPa; Young's modulus 280–390 GPa.

-

Thermal properties: operating temperature up to 1800 °C, low CTE 7–8.3 × 10⁻⁶ K⁻¹.

-

Chemical resistance: inertness at pH 0–14 (except hot HF and HCl).

-

Wear resistance: amount <0,05 mm3/N·m, to 10 times higher, than steel.

-

Biocompatibility: ISO compliance 10993, low ion emission, FDA approved for food contact.

| Property |

Units. change. |

Test standard |

92% Al₂O₃ |

95% Al₂O₃ |

99% Al₂O₃ |

99,9% Al₂O₃ |

99,99% Al₂O₃ |

| Material |

– |

– |

Pale white |

Pale white |

White |

Translucent |

Transparent |

| Density |

g/cm³ |

ISO 18754 |

3,60 |

3,70 |

3,90 |

3,98 |

3,99 |

| Bending strength |

MPa |

ASTM C1161 |

250 |

300 |

400 |

450 |

500 |

| Compressive strength |

MPa |

ASTM C773 |

2000 |

2500 |

3000 |

3500 |

4000 |

| Young's modulus |

GPa |

ASTM C1198 |

280 |

320 |

350 |

380 |

390 |

| Fracture toughness |

MPa·m¹/² |

ASTM C1421 |

3,0 |

3,5 |

4,5 |

5,0 |

5,5 |

| Poisson's ratio |

– |

ASTM C1421 |

0,22 |

0,22 |

0,22 |

0,22 |

0,22 |

| Hardness HRA |

HRA |

Rockwell 45N |

90 |

92 |

94 |

95 |

96 |

| Vickers hardness |

HV |

ASTM E384 |

1100 |

1300 |

1600 |

1900 |

2000 |

| Coefficient of thermal expansion |

10⁻⁶ K⁻¹ |

ASTM E831 |

7,0 |

7,5 |

8,0 |

8,2 |

8,3 |

| Thermal conductivity |

W/m·K |

ASTM E1461 |

18 |

22 |

28 |

32 |

35 |

| Thermal shock resistance |

ΔT (°C) |

– |

200 |

250 |

350 |

450 |

500 |

| Max. temperature of use in an oxidizing atmosphere |

°C |

No load |

1400 |

1500 |

1650 |

1750 |

1800 |

| Max. temperature for use in a reducing or inert atmosphere |

°C |

No load |

1300 |

1400 |

1550 |

1650 |

1700 |

| Volume resistance at 20°C |

Ohm cm |

ASTM D257 |

10¹² |

10¹³ |

10¹⁴ |

10¹⁵ |

10¹⁶ |

| Dielectric strength |

kV/mm |

ASTM D149 |

15 |

18 |

22 |

28 |

30 |

| Dielectric constant (1 MHz) |

– |

ASTM D150 |

9,0 |

9,2 |

9,6 |

9,9 |

10,0 |

| Dielectric loss angle at 20°C, 1 MHz |

tan δ |

ASTM D150 |

6×10⁻⁴ |

4×10⁻⁴ |

2×10⁻⁴ |

1×10⁻⁴ |

5×10⁻⁵ |

Note: Values vary depending on grain size/porosity; nano grades can exceed benchmarks.

Benchmarking for Precision Engineering

Aluminum oxide shines in economical, high-load roles, often outperforming metals in durability. Below is an extended comparison:

| Characteristic |

Aluminum Oxide Ceramics |

Structural ceramics (e.g., zirconium) |

Glass |

Steel |

Tungsten carbide |

| Strength and Toughness |

High compression (fragile in tension) |

Outstanding (phase change strengthening) |

Average, fragile |

High stretch/compression |

Excellent (fragile) |

| Thermal stability |

Excellent (melting 1800°C) |

Excellent (2700°C) |

Average (~500°C softening) |

Decreasing >800°C |

Fireproof |

| Wear resistance |

Exceptional (μ 0.1–0.4) |

Highest level |

Average |

Moderate (rusts) |

Elite |

| Corrosion resistance |

Highly inert (pH 0–14) |

Excellent |

Good to acids |

Inclination without coating |

Chemical-resistant |

| Transparency |

Opaque (translucent in high quality) |

Opaque (translucent YSZ) |

Transparent |

Opaque |

Opaque |

| Biocompatibility |

High (ISO 10993) |

Medical grade |

Varies |

Varies (allergenic) |

Varies |

| Electrical insulation |

Excellent (>10¹⁶ Ohm cm) |

Excellent |

good |

Conductive |

Conductive |

| Magnetic behavior |

Non-magnetic |

Non-magnetic |

Non-magnetic |

Often magnetic |

Non-magnetic |

| Price (per kg) |

Low ($5–20) |

Moderate ($50–100) |

Very low |

Low |

High ($100+) |

Industry data; Cost-effectiveness of aluminum oxide favors high-volume applications, such as grinding.

Advantages of aluminum oxide ceramics

Durability: Hardness extends service life by 5–15 times compared to metals in abrasives, reducing downtime by 40%.

Adaptability: Operation from -200°C to 1800°C, universal for cryogenic to furnace use.

Visual/functional finishing: White translucency helps inspection; polishing to Ra 0,01 µm.

Minimal Maintenance: Inertness reduces corrosion repairs in chemicals/minerals.

Economic value: On 50% cheaper than carbides, ROI through pollution reduction.

Environmental safety: Recyclable, low energy Bayer process; non-toxic for pharma/food.

Reliable Performance: Fatigue resistance >107 cycles; rigid for precision machines.

Friction durability: Low wear in suspensions, energy saving 15–25%.

Friendly to the body: Osseointegration >90% in implants.

Anti-corrosion: Withstands acids without HF, vital for processing.

Thermal efficiency: Isolates electronics, dissipates in radiators.

Real-life applications of aluminum oxide ceramics

Aluminum oxide components dominate there, where toughness meets economics, from sanding to insulation. Their abrasion resistance and cleanliness make them vital. Here's an extended review with the top 10:

Top 10 Applications in Modern Industries

- Grinding media (Al₂O€): Grinds cement clinker/minerals, increasing mill efficiency by 20% low pollution.

- Wear resistant linings: Protects chutes in mining, extending the deadline by 10 times compared to steel.

- Electrical insulators: BB bushings in transformers, >25 kV/mm strength.

- Pump hoses: Abrasion resistant in suspensions, reducing failures by 50%.

- Pads: LED/5G boards, thermal stability for high power.

- Orthopedics: Thigh balls, biocompatibility reduces revisions by 30%.

- Spark plugs: Withstand 1000°C ignition, reliable in EV.

- Nozzles: Spraying abrasives in a sandblaster, uniform flow.

- Crucibles: Inert for melting metals, no pollution.

- Thermal screens: Aerospace, protection 1700°C.

Industrial

Al₂O₃ (clinker to powder, energy saving) and minerals (ore in fines, uniform RPS). Wear-resistant parts line the mills.

Structural

Bushings/insulators for guides; substrates for PP.

Electronics

Sensors/capacitors with insulation; uniform heaters.

Medicine

Hip joints are hard/biocompatible; precision dental instruments.

Aerospace

Engine Screens Extreme Temperatures; oxidation-proof coatings.

Automotive

Stress-resistant candles; low friction linings.

Optics

Scratch-proof lenses.

Laboratory

Crucibles inert experiments.

Aluminum oxide combination cements its role in impactful innovation, market up $106 billion k 2032 year.

Translucent and high quality aluminum: Optical and functional advances

Although standard aluminum oxide is opaque, stamps >99,5% reach translucency (40–60% transmittance), allowing optics like sapphire windows. Problems: grain control during sintering for clarity. Methods: HIP or doping for LED phosphors. Applications: biomedical imaging, photonics. Prospects: nano alumina for 90% transparency, revolutionizing displays.

How aluminum oxide ceramic components are made?

Preparation of raw materials

The process begins with purchasing high quality aluminum oxide powder. This powder is obtained from bauxite using the Bayer process and can be sprayed for uniform particle size.

Grinding and mixing

The powder is mixed with binders, plasticizers and additives, then ball milled to achieve uniform particle distribution.

Molding

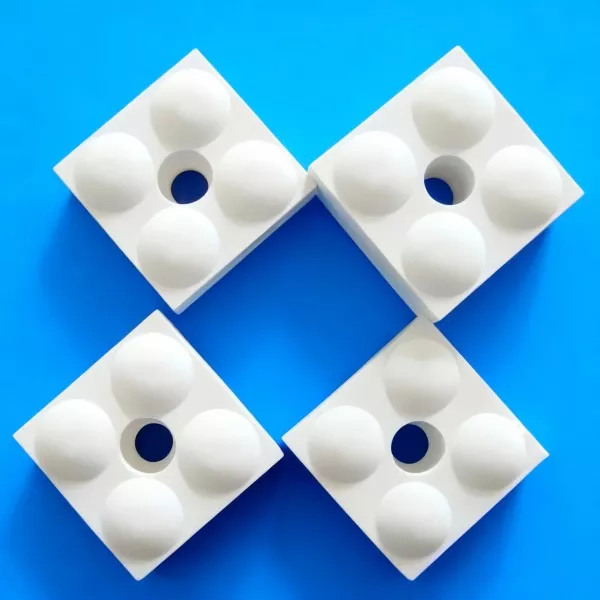

- Dry pressing: for simple shapes (balls, bushings).

- Die casting: for complex structural parts.

- Suspension casting: for wear-resistant linings.

- Extrusion: for pipes and rods.

Removing binders

The workpiece undergoes thermal or chemical debinding to prevent defects.

Sintering

Parts are sintered in a high-temperature furnace. Particles merge, increasing density and strength. Temperature and atmosphere are critical parameters.

Post-sintering processes

- Processing: diamond tools.

- Sanding and polishing: smooth surfaces for Al₂O₃ balls.

- Coating: applying thin protective layers.

Quality control

Defect tests, dimensions, strength, x-ray diffraction, microscopy.

Packaging and Shipping

Finished parts are packaged and sent to customers or for further processing.