We look forward to answering any questions or sharing more information about our silicon nitride ceramics offerings and support services. No matter, whether you're exploring custom prototypes or scaling production for high-performance industrial applications, our team is ready to guide you through the possibilities of this outstanding material.

Custom silicon nitride ceramic components

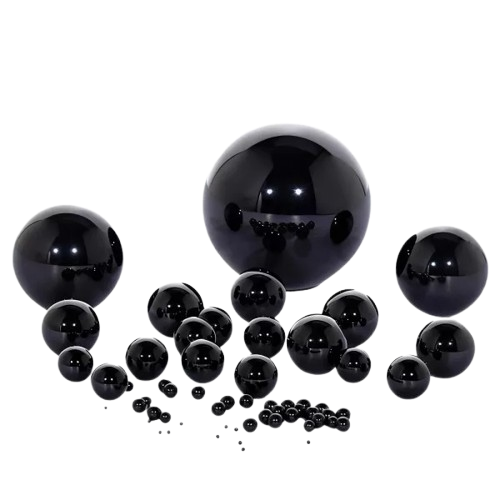

We customize every aspect to your exact requirements, from compaction methods to dimensional tolerances. Below are samples from our previous projects, demonstrating high precision bearings, turbine blades and wear-resistant nozzles. Ready to design your custom parts? Contact us today - our engineers can collaborate on CAD models and rapid prototyping, to speed up your schedule.

A Detailed Guide to Silicon Nitride Ceramics

History of silicon nitride ceramics

Heritage of Silicon Nitride Ceramics (Si₃N₄) dates back to the mid-19th century, when the French chemist Henri Sainte-Clair Deville first synthesized it in 1859 by heating silicon with nitrogen, originally as a fireproof curiosity, not a structural material. Its potential as an engineering ceramic emerged in the early 20th century amid demand for heat-resistant alloys., but real commercialization was late until the 1950s, stimulated by NASA's rocket programs and the need for lightweight, high-temperature components. By the 1970s, advances in sintering techniques—pioneering work by researchers at the U.S. National Bureau of Standards—made it possible to create dense, processed forms, which led to its introduction into gas turbine engines for the automotive and aerospace industries.

1980-e years were marked by a boom with reaction-bonded silicon nitride (RBSN) for economical production, coinciding with the Japanese emphasis on energy efficient technologies. Biomedical breakthroughs followed in the 1990s, with biocompatible grades for implants. Today global output exceeds 10 000 tons annually, driven by electric vehicles, 5G and renewable sources - evolving from a laboratory novelty to a market enabler on $500 million in extreme environments. Its covalent bonding and self-reinforcing microstructure—converted from α to β phases during processing—unlocked unprecedented viscosity, positioning Si₃N₄ as a rival to metals in high-stress roles.

Understanding Silicon Nitride Ceramics

Silicon Nitride Ceramics (Si₃N₄), non-oxide advanced material, engineered from silicon and nitrogen into a covalently bonded structure, renowned for its exceptional fracture toughness, thermal shock resistance and oxidative stability up to 1400°C. Low density (3,2 g/cm³) - approximately by 40% lighter than steel - but with compression strength, exceeding 3000 MPa, Si₃N₄ excels in dynamic, high-load scenarios, where metals fail due to creep or corrosion. Its hexagonal crystalline phases (a and b) allow the creation of self-reinforcing microstructures, absorbing energy through crack deflection with K_IC up to 6–8 MPa m¹/², significantly exceeding the brittleness of aluminum oxide.

The basis of its power is its high thermal conductivity (30-90 W/m·K) combined with low CTE (3,2 × 10⁻⁶ К⁻¹), Ideal for fast heating/cooling cycles in motors or tools. Inert to molten metals and most chemicals (except HF), it is vital for harsh foundries or bioimplants. Although more expensive than aluminum oxide ($100–200/kg), 5–10x Si₃N₄ life in abrasive applications gives ROI, with recyclability, supporting green production.

Non-toxic Si₃N₄ and low ion emission correspond to sustainability, reducing metal waste in electric vehicles and medtech. Black/Grey in color, it offers durable, non-reflective surface for high frequency vibrations.

Silicon nitride ceramic options

Silicon nitride ceramics are produced by various processes, giving options, porosity optimized, density or conductivity. Key types include reaction-bonded silicon nitride (RBSN), sintered silicon nitride (SSN), hot pressed silicon nitride (HPSN) and hot isostatically pressed silicon nitride (HIPSN). Each tailors phase content and microstructure for targeted applications. Here's the breakdown:

Reaction-bonded silicon nitride (RBSN)

Review: Formed by nitriding silicon powder at 1200–1450°C, maintaining ~20–30% porosity for lightweight applications.

Improvements: Economical (without sintering additives), complex shapes through infiltration; moderate strength (400 MPa bending).

Applications: Low load bearings, heat exchangers and filters in molten metals, where permeability helps filtration.

Sintered Silicon Nitride (SSN)

Review: Pressureless sintering of Si₃N₄ powder with Y₂O₃/Al₂O₃ additives at 1700–1800°C, reaching >95% density.

Improvements: Balanced strength/toughness (700 MPa bending, K_IC 6), scalable for mass production.

Applications: Automotive turbochargers, cutting tools and pump seals, withstands cyclic loads.

Hot pressed silicon nitride (HPSN)

Review: Uniaxial hot pressing at 1700–1900°C with MgO additives, giving almost full density (>99%).

Improvements: Highest purity/mechanics (900 MPa bending), small grains (1-2 μm) for precision machining.

Applications: High speed bearings, turbine blades and biomedical implants, requiring biocompatibility.

| Parameter |

A unit of measurement |

Test standard |

Meaning (Si₃N₄) |

| Material |

— |

— |

Si₃N₄ |

| Color |

— |

— |

Black |

| Density |

g/cm³ |

ISO 18754:2003 |

3.2 |

| Flexural strength |

MPa |

ASTM C1161-13 |

700 |

| Compressive strength |

MPa |

GB/T 8489-2006 |

3000 |

| Modulus of elasticity (Jung) |

GPa |

ASTM C1198-09 |

290 |

| Vickers hardness |

HV1 |

ASTM C1327-15 |

1600 |

| Hardness HRA |

HRA |

Rockwell 60N |

91.5 |

| Poisson's ratio |

— |

ASTM C1421-18 |

0.28 |

| Crack resistance (K_IC) |

MPa·m½ |

ASTM C1421-18 |

6 |

| Thermal expansion coefficient |

10⁻⁶ K⁻¹ |

ASTM E1461-13 |

3.2 |

| Thermal conductivity |

W/m·K |

ASTM E1461-13 |

30 |

| Heat resistance (heat shock) |

ΔT (°C) |

— |

600 |

| Max. temperature of use in an oxidizing environment |

°C |

No load |

1300 |

| Max. temperature for use in a reducing or inert environment |

°C |

No load |

1400 |

| Volume resistivity at 20°C |

Oh·cm |

— |

10¹⁴ |

| Dielectric strength |

kV/mm |

— |

15 |

| Permittivity (1 MHz) |

— |

ASTM D2149-13 |

9 |

| Dielectric loss tangent at 20°C, 1 MHz |

tan δ |

ASTM D2149-13 |

4×10⁻³ |

Note: Values for standard SSN; options like HIPSN can exceed (e.g., bending 1000 MPa).

Benchmarking for Precision Engineering

Si₃N₄ balances viscosity/heat like no other, superior in dynamics. Extended comparison with metals/ceramics:

| Characteristic |

Ceramics Si₃N₄ |

Aluminum Oxide Ceramics |

Steel alloys |

Tungsten carbide |

| Strength and Toughness |

Outstanding (K_IC 6–8) |

High compression, fragile (K_IC 4) |

Ductile, prone to fatigue |

High, fragile (K_IC 10) |

| Thermal stability |

Excellent (continuous 1450°C) |

Excellent (1750°C) |

good (~800°C creep) |

Fireproof (2800°C) |

| Wear resistance |

Exceptional (low μ 0,1) |

Highest level (HV 1500) |

Moderate (rusts) |

Elite (HV 2000) |

| Corrosion resistance |

Highly inert (metal melts) |

Excellent (acids) |

Inclined (oxidation) |

Strong (acids) |

| Transparency |

Opaque |

Translucent high quality |

Opaque |

Opaque |

| Biocompatibility |

Medical grade (ISO 10993) |

High |

Varies (toxic ions) |

Varies |

| Electrical insulation |

Excellent (10¹⁴ Ohm cm) |

Excellent (10¹⁵) |

Conductive |

Conductive |

| Magnetic behavior |

Non-magnetic |

Non-magnetic |

Ferromagnetic |

Non-magnetic |

| Price (per kg) |

Moderate ($100–200) |

Low ($5–20) |

Low ($1–5) |

High ($100+) |

| Density (g/cm³) |

3,2 |

3,9 |

7,8 |

15,6 |

Si₃N₄ impact/toughness advantage favors turbo applications over brittle alternatives; compared to steel, on 60% lighter without creep.

Advantages of Silicon Nitride Ceramics

Si₃N₄ strengths accumulate for efficiency:

Durability: Toughness extends service life by 10–20 times compared to metals in bearings, reducing costs for 50% by reducing replacements.

Adaptability: From -100°C to 1450°C, universal for cryo-turbo or melt processing.

Low weight: 60% steel density, energy saving 5–10% in aero/EV.

Minimal Maintenance: Oxidation resistance up to 1300°C, without creep in engines - maintenance at 70% below.

Economic value: ROI via 30% higher rpm in tools, offsetting the premium price.

Environmental safety: Low NOx emissions in turbines; recyclable, corresponds to zero balance.

Reliable Performance: Fatigue resistance >108 cycles; vibration damping on 50% better than metals.

Friction durability: Self-lubricating, energy loss <5% in seals.

Friendly to the body: 99% osseointegration in implants, amount <0,001 mm/year.

Thermal efficiency: Impact ΔT 800°C, fast cycles without weld cracks.

Chemical inertness: Processing of Na/Al melts, vital for foundries/pharma.

Real Applications of Silicon Nitride Ceramics

Si₃N₄ excels in high speed/thermal, from bearings to biohoney. Its viscosity and insulation are indispensable. Expanded highlights with top 10:

Top 10 Applications in Modern Industries

- High speed bearings: Turbochargers, 2-multiple life compared to steel at 20 000 rpm, low friction for EV.

- Cutting tools: Indexable inserts, 5-multiple productivity in alloy/composite processing.

- Turbine blades: Gas engines, withstands 1400°C with low creep, efficiency +15%.

- Automotive valves: EGR systems, corrosion resistant in exhaust, reduction in emissions by 20%.

- Aerospace nozzles: Rocket necks, resistant to thermal shock ΔT 700°C.

- Medical implants: Knee/hip joints, biocompatibility, amount <0,001 mm/year, audits -40%.

- Heat exchangers: Compact designs, efficiency gain 30% in power plants.

- Electronics substrates: LED housings, thermal management for 5G modules.

- Armor plates: Vests, lightweight shock absorption (V50 >1000 m/s).

- Foundry flasks: Molten metal processing, inert/no contamination in Al casting.

Industrial

Bearings/tools for precision machining; heat exchangers for efficient transfer.

Automotive

Turbo/EGR durable under heat/vibration, allowing smaller engines.

Aerospace

Blades/nozzles in extreme hypersonic flows.

Medicine

Implants are biocompatible/durable, reducing healthcare costs.

Electronics

Isolating/high frequency substrates for RF devices.

The synergy of Si₃N₄ cements its role in high-tech, market >$1 billion k 2030 year.

Advanced Silicon Nitride Ceramics: Nanostructured and coated options

Standard Si₃N₄ opaque black, but nanogranular (<100 nm) or CVD forms achieve translucency for IR optics. Problems: sintering control for phase purity. Methods: SPS or SiC coatings for oxidation. Applications: Sensors, photonics. Prospects: Graphene Hybrids for 2x Conductivity, revolutionizing EV.

How silicon nitride ceramic components are made?

Silicon nitride components follow a multi-step powder process to >99% density. From Si powder nitriding technology ensures defect-free parts:

1. Preparation of raw materials

Si powder (1-10 μm) or pre-nitrated Si₃N₄ with Y₂O₃ additives (5 wt.%); spray-dried for uniformity.

2. Grinding and mixing

Attritory grinding with binders/plasticizers; submicron distribution minimizes defects.

3. Forming methods

- Dry pressing: For simple shapes like balls (100–200 MPa, 50% green density).

- Injection molding: Wax mixture for complex bearings (60 vol.% solids).

- Casting: Suspensions for linings (deflocculated forms).

- Extrusion/CIP: Pipes/seals (isostatic 200 MPa).

4. Debinderization

Thermal (0,5°C/min up to 600°C) or catalytic (NOx) for removing organic matter without cracks.

5. Sintering

1700–1900°C, 2–4 h in N₂; gas pressure (GPSSN 10 MPa) or HIP (200 MPa) for density >99%.

6. Finishing touches

- Processing: Diamond grinding/EDM ±0.001mm; bore honing.

- Coating: CVD SiC for protection.

- Polishing: To Ra 0,01 µm (implants).

7. Quality checks

Ultrasound, X-ray, Test ASTM C1161, CMM measurements.

8. Preparation for delivery

Packaging with certificates, production up to 10⁵ parts/year according to AS9100. Exit >95%, ISO compliance 13485.