1. Enhanced UV Absorption

2. Optical Transparency

3. Chemical Stability

4. Exceptional Conductivity

5. Photocatalytic Power

Nano-zinc oxide is an inorganic active agent and vulcanization accelerator in rubber industry. Its application in rubber has the characteristics of fast vulcanization speed and high conversion rate into zinc sulfide. It can improve the smoothness, mechanical strength, temperature resistance and aging resistance of rubber products, especially wear resistance. Used in paints, inks, coatings, and plastics, it can improve the covering force and tinting power of the product, and can be used as a flux for emulsifying glazes in the ceramic industry.

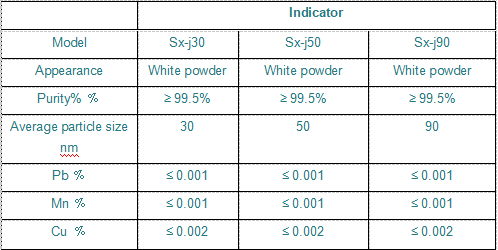

Technical indicators:

Application scope:

1. Vulcanizing active agents in rubber industry, catalysis and additives in petrochemical industry are automobile tires, aircraft tires, industrial cable industries and zinc oxide ceramics.

2. Paint, transparent rubber, latex and plastic industries can increase product strength, compactness, adhesion and smoothness.

3. Electronic industry and instrument industry, manufacturing electrical devices, radios, wireless fluorescent lamps, image recorders, variable resistance meters, phosphors.

4, functional fibers, textiles in products.

Packaging:15kg/barrel.

Nano Zinc Oxide, available in different grades such as UG-J30, UG-J50, and UG-J90, represents a range of specialized nanomaterials with unique properties tailored to various industrial applications. Here is a comprehensive description of these nano zinc oxide grades and their significance in industry:

Chemical Composition: Nano Zinc Oxide (ZnO) is composed of zinc (Zn) and oxygen (O) atoms, with the chemical formula ZnO. These nano zinc oxide grades maintain this fundamental composition but vary in particle size and specific properties.

Particle Size: The grades are named based on their average particle size:

Purity: High purity is a key characteristic of these nano zinc oxide grades, often exceeding 99%, ensuring minimal impurities that could affect industrial processes and product quality.

Appearance: Nano Zinc Oxide UG-J30, UG-J50, and UG-J90 typically appear as fine white powders with varying degrees of brightness and uniformity, depending on the specific grade.

Applications:

Optical Properties: Nano zinc oxide exhibits high transparency in the visible spectrum, making it suitable for applications where optical clarity is crucial, such as in transparent coatings and sunscreens.

Photocatalytic Activity: It possesses photocatalytic properties, allowing it to catalyze certain chemical reactions when exposed to light. This property is beneficial for environmental applications like air purification and water treatment.

Safety: These nano zinc oxide grades are generally considered safe for industrial use. However, precautions should be taken to minimize exposure during handling and manufacturing, especially in powdered form.

Storage: They should be stored in dry, cool, and well-ventilated industrial environments to prevent moisture absorption and ensure long-term stability.

In summary, Nano Zinc Oxide grades UG-J30, UG-J50, and UG-J90 are specialized nanomaterials with varying particle sizes, offering tailored properties for a wide range of industrial applications. Their nanoscale characteristics make them valuable components in products and processes, contributing to improved performance, safety, and quality across various