Zirconium dioxide ceramics (ZrO₂): Properties, options, applications and innovations

We look forward to answering any questions or sharing more information about our zirconia ceramic offerings and support services. No matter, whether you're exploring custom prototypes or scaling production, our team is ready to guide you through the possibilities of this outstanding material.

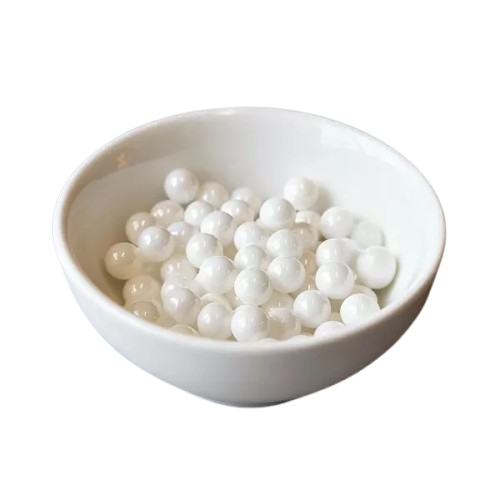

Purchase or production of custom-made zirconium ceramic products

We professionally provide services for the purchase and production of custom-made zirconium ceramic products, covering a full range of products, including zirconium grinding balls, bearing balls and structural components. We can precisely tailor technical specifications and operating parameters to meet the individual needs of various industries, such as mining, energy, electronics and medicine, efficiently delivering high quality products, which fully satisfies the basic needs of industrial production in the field of grinding, transmissions and structural supports.

A Comprehensive Guide to Zirconium Ceramics

-

History of zirconium ceramics: The history of zirconium ceramics begins at the end of the 18th century, when the German chemist Martin Heinrich Klaproth first isolated zirconium from the mineral zircon, naming it after the Persian word "zargun", meaning "golden". In the 19th century, zirconium found its initial industrial use as an abrasive in grinding wheels and polishing tools., using its exceptional hardness. The 20th century was marked by a turning point, when researchers discovered the polymorphic nature of zirconium - its ability to transition between monoclinic, tetragonal and cubic crystalline phases, - which opened up unprecedented viscosity due to phase transformations, caused by stress. This breakthrough propelled zirconium into structural ceramics, especially in aerospace and refractories in the post-war period. In the 21st century, advances in stabilization methods, such as yttrium doping, expanded the role of zirconium in the biomedical and energy industries. Today, global production exceeds millions of tons annually, driven by demand for medical implants and solid oxide fuel cells (SOFC). Its evolution reflects a broader trend in materials science: from primitive abrasives to engineered solutions for extreme conditions, with ongoing research, pushing the boundaries in nanotechnology and additive manufacturing.

-

Understanding Zirconium Ceramics: Zirconium dioxide ceramics (ZrO₂) represents a powerful class of advanced materials, renowned for its superior durability, durability and resistance to abrasion and chemical attacks. Chemically inert and highly thermally expandable, Zirconium ceramics stand out among oxide ceramics in their ability to maintain structural integrity under thermal shock, making it indispensable in high-risk environments. This adaptive substance can be formed into a variety of forms - from complex micro-components to large-scale refractories, - positioning it as the preferred option in several sectors. Zirconium's performance is based on its polymorphic behavior: at room temperature it takes on a monoclinic structure (baddeleit), but when heated or stressed transforms into denser tetragonal or cubic phases, absorbing energy and preventing crack propagation - mechanism, known as phase change strengthening. This unique feature, combined with melting point, exceeding 2700°C, makes it ideal for screenplays, requiring the highest performance, such as orthopedic implants, prosthetic dental restorations and precision cutting instruments. Besides, it plays a key role in the manufacture of electronic components, such as sensors and capacitors, where its ionic conductivity facilitates the transport of oxygen ions at elevated temperatures.

-

Zirconium ceramic options: Zirconium ceramics are available in several formulas, each tailored with stabilizers to optimize performance and mitigate volume expansion issues, inherent in pure phase transitions of ZrO₂. Key differences include standard zirconia ceramic, yttrium-stabilized zirconium and aluminum-zirconium composites. These options are designed to lock in the desired phases, improving stability and mechanical properties for specific applications. Here is a detailed analysis:

Standard zirconium ceramic (ZrO₂)

-

Review: Pure white crystalline oxide, characterized by outstanding resistance to degradation and chemical inertness, with natural monoclinic phase at ambient conditions.

-

Crystal phases: Expresses monoclinic (room temperature), tetragonal (1170–2370°C) or cubic (above 2370°C) structures depending on temperature and processing.

-

Applications: Its mechanical superiority and abrasion resistance make it ideal for dentures, cutting edges and premium ceramic products, such as imitation jewelry (cubic zirconia). However, pure forms are prone to cracking without stabilization.

Yttrium-stabilized zirconium (ZrO₂-Y₂O₃, YSZ)

-

Review: Mixed with 3–8% yttrium oxide (AND₂OR₃) for fixation of cubic or tetragonal phase, often leading to translucent variants.

-

Improvements: Provides a wide range of thermal stability (up to 1000°C) and high ionic conductivity for cubic structure, crucial for electrochemical devices.

-

Applications: Required in solid oxide fuel cells, gas sensors and systems, subject to heat, where is the mobility of oxygen ions vital; also popular in dental applications for its aesthetics.

4. Aluminum-zirconium ceramics (Al₂O₃-ZrO₂)

-

Description: Composite material, combining the properties of aluminum oxide (Al₂O₃) and zirconium dioxide (ZrO₂).

-

Stability: Adding aluminum oxide increases the strength and wear resistance of zirconium.

-

Application: Used in abrasive materials due to their high hardness and crack resistance - in cutting tools, grinding wheels and other products, subject to heavy wear.

5. Mg-PSZ (partially magnesium stabilized zirconium)

-

Description: Zirconia type, partially stabilized with magnesium oxide, containing a mixture of tetragonal and monoclinic phases.

-

Stability: The combination of phases gives the material a unique combination of strength and toughness.

-

Application: Due to increased crack resistance, Mg-PSZ used in parts, requiring high resistance to cracking - for example, in bearings, cutting tools and other wear-resistant elements.

Conclusion

Zirconium ceramics is a versatile material, the properties of which can be changed by adding various stabilizers. magnesium-, yttrium, alumo- and partially stabilized zirconium varieties have unique characteristics, making them suitable for a wide range of industrial applications.

| Property |

Units. change. |

Test method |

ZrO₂ (Standard) |

ZrO₂-Y₂O₃ |

ZTA (Aluminum-zirconium) |

|

| Material |

– |

– |

White |

White |

White/Gray |

|

| Density |

g/cm³ |

ISO 18754:2003 |

5,68 |

5,95–6 |

4,1–4,3 |

|

| Bending strength |

MPa |

ASTM C1161-13 |

400–600 |

1000 |

500–800 |

|

| Compressive strength |

MPa |

GB/T 8489-2006 |

1800 |

2200 |

2000–2500 |

|

| Young's modulus |

GPa |

ASTM C1198-09 |

200 |

210 |

300–350 |

|

| Fracture toughness |

MPa·m¹/² |

ASTM C1421-18 |

4–5 |

8 |

5–7 |

|

| Poisson's ratio |

– |

ASTM C1421-18 |

0,3 |

0,3 |

0,25 |

|

| Hardness (HRA) |

HRA |

Rockwell 60N |

85 |

90 |

92 |

|

| Vickers hardness |

HV1 |

ASTM C1327-15 |

1100 |

1450 |

1600–1800 |

|

| Thermal expansion |

10⁻⁶ K⁻¹ |

ASTM E1461-13 |

10 |

10 |

7–8 |

|

| Thermal conductivity |

W/m·K |

ASTM E1461-13 |

2,5 |

3 |

20–25 |

|

| Thermal shock resistance |

ΔT (°C) |

– |

300 |

400 |

250 |

|

| Max. pace. (oxidation) |

°C |

No load |

1000 |

1000 |

1500 |

|

| Max. pace. (recovery/inert) |

°C |

No load |

850 |

1000 |

1400 |

|

| Volume resistance (20°C) |

Oh·cm |

– |

10¹⁰ |

10¹² |

10¹⁴ |

|

| Dielectric strength |

kV/mm |

– |

12 |

15 |

20 |

|

| Dielectric constant (1 MHz) |

– |

ASTM D2149-13 |

25 |

30 |

9–10 |

|

| Dielectric losses (20°C, 1 MHz) |

tan δ |

ASTM D2149-13 |

3×10⁻³ |

2×10⁻³ |

1×10⁻³ |

|

Note: Values may vary depending on grain size and porosity; advanced options, such as nano-YSZ, may exceed these standards.

Benchmarking for Precision Engineering

Zirconium excels in scripts, requiring a balance of viscosity and hardness, often outperforming alternatives in dynamic loads. Below is an extended comparison:

| Characteristic |

Zirconium ceramics |

Structural ceramics (e.g., aluminum) |

Glass |

Steel |

Tungsten carbide |

|

| Strength and Toughness |

Outstanding (phase change strengthening) |

Solid, but fragile (K_IC ~4 MPa·m¹/²) |

Average, fragile |

High stretch/compression |

Excellent (but fragile) |

|

| Thermal stability |

Strong (melting up to 2700°C) |

Excellent (high melting temperature) |

Average (softens ~500°C) |

Decreases when heated (>800°C) |

Excellent (refractory) |

|

| Wear resistance |

Exceptional (low friction coefficient 0.1–0.3) |

good |

Average |

Average (rusts) |

Highest level |

|

| Corrosion resistance |

Highly resistant (inert to acids/bases) |

Usually good |

Good to acids |

Inclination without coating |

Strong to chemicals |

|

| Transparency |

Opaque (translucent in YSZ) |

Opaque |

Transparent |

Opaque |

Opaque |

|

| Biocompatibility |

Medical grade (ISO 10993) |

Varies |

Varies |

Varies (allergenic) |

Varies |

|

| Electrical insulation |

Excellent (r >10¹² Oh·cm) |

Strong |

good |

Conductive |

Conductive |

|

| Magnetic behavior |

Non-magnetic |

Non-magnetic |

Non-magnetic |

Often magnetic |

Non-magnetic |

|

| Price (per kg) |

Moderate ($50–100) |

Low ($10–20) |

Very low |

Low |

High ($100+) |

|

Data taken from industry standards; Zirconium's toughness advantage makes it preferred for impact applications.

Advantages of zirconium ceramics

The benefits of zirconium accumulate over time, offering life cycle savings:

Durability: High toughness and strength extend service life by 5 to 10 times compared to metals in wear applications.

Adaptability: Runs from subzero (-50°C) to extreme heat (1000°C+).

Visual harmony: White opacity, similar to tooth enamel, ideal for dental aesthetics; paintable for custom designs.

Minimal Maintenance: Chemical inertness reduces wear and replacement in corrosive environments.

Economic value: Durability reduces long-term costs, minimizing downtime.

Environmental safety: Non-toxic, recyclable and free of heavy metals for a wide range of, risk-free deployment.

Economic value: Durability reduces long-term costs, minimizing downtime.

Environmental safety: Non-toxic, recyclable and free of heavy metals for a wide range of, risk-free deployment.

Reliable Performance: Easily copes with intense stress, with fatigue resistance >106 cycles.

Friction durability: Outperforms rivals in abrasive environments, reducing energy loss.

Friendly to the body: Safe for implants and dentures, with osseointegration indicators >95%.

Anti-corrosion: Withstands harsh chemical influences, extending service in petrochemicals.

Thermal efficiency: Low conductivity effectively insulates, increasing energy savings in high temperature systems.

Real Applications of Zirconium Ceramics

Zirconium components shine in various sectors thanks to their mechanical strength,

heat resistance and inertness. Their biocompatibility, hardness and resistance to degradation

make them indispensable. Below are modern applications, including top 10 industries.

Top 10 Applications in Modern Industries

- Zirconia Ceramic Grinding Balls: High-density grinding media for ball mills

when grinding minerals, ceramic and chemical powders. Service life is 5–10 times longer

steel balls, 20–30% increase in efficiency.

- Medical Implants: Hip and knee endoprostheses, biocompatibility, high strength

(KIC 8 MPa·m¹/²), reduction in the frequency of re-operations by 30%.

- Dental Restoration: Crowns, bridges and implants with high translucency and strength.

- Aerospace Engine Components: Turbine blades, heat protection elements, resistance up to 1000 °C.

- Automotive Oxygen Sensors: Lambda probes, improving combustion efficiency and reducing emissions by 20%.

- Solid Oxide Fuel Cells (SOFC): Electrolyte layers at 600–1000 °C for clean energy.

- Precision Cutting Tools: Knives and cutters with hardness 8.5 Moosa, longer service life 5 once.

- Electronic Sensors and Capacitors: High Temperature Capacitors and Sensors,

insulation resistance 10¹² Ω cm.

- Optical Lenses and Jewelry: High refractive index (n = 2.15), cubic zircon for jewelry.

- Industrial Wear-Resistant Linings: Wear-resistant coatings for mining, increase in service life 10 once.

Applications of zirconium are growing, the market is forecast to grow 7% per year before 2030 year.

Colored zirconium ceramic: Aesthetic and functional achievements

Modern colored zirconium ceramics use stable pigments (Fe₂O₃, V₂O₅, soot),

withstands temperatures up to 1400 °C. Technologies include powder alloying, infiltration after firing

and 3D printing. Used in dentistry, wearable devices, decorative tiles and jewelry.

How zirconium ceramic components are made?

The production of zirconium parts includes eight main stages.

1. Source of raw materials

ZrO₂ powder is used 99,5%+, stabilized Y₂O₃ (3–8%). PVA binders and dispersants are added.

2. Mixing and grinding

The powder is mixed with organic additives, crushed to 0.1–5 microns.

3. Forming methods

- Dry pressing - pressure up to 100 MPa.

- Injection Molding - Complex Geometries, 60% solids.

- Casting Molding - Plaster Molds.

- Belt casting - for thin plates 0.1–1 mm.

- Isostatic pressing (CIP/HIP).

- 3D-stamp.

4. Removing the binder

Slow heating to 400–600 °C, binder pyrolysis, catalytic or solution debinderization.

5. Object (sintering)

Temperature 1400–1700 °C, density >99%. HIP to 200 MPa increases strength by 20%.

6. Finishing touches

- CNC grinding, ultrasound, EDM.

- Polishing to Ra < 0.01 µm.

- Coatings: EB-PVD, hydroxyapatite.

7. Quality check

- Ultrasound, X-ray CT, ASTM C1161 strength tests.

- CMM measurements, SEM defect analysis.

8. Preparation for delivery

Package, marking, certificates, AS9100/ISO compliance 13485.

Production output >95%.